Two schools containing potentially dangerous concrete named by Highland Council

It has been produced to help estates' teams/site managers understand how to identify Reinforced Autoclaved Aerated Concrete (RAAC) panels in floors, walls, eaves and roofs (pitched and flat). This publication replaces previous guidance issued by the DfE entitled 'Reinforced Autoclaved Aerated Concrete: Estates guidance' dated December 2022.

Unions warn many school buildings ‘at risk of collapse’ News

Identifying problematic RAAC planks. The potential for sudden failure of reinforced autoclaved aerated concrete planks has been highlighted recently. So how can surveyors tell whether the material has been used for construction and identify the warning signs? Excessive deflections and transverse cracking were thought to be a key warning sign of.

The risks of Reinforced Autoclaved Aerated Concrete in building construction JMS Engineers

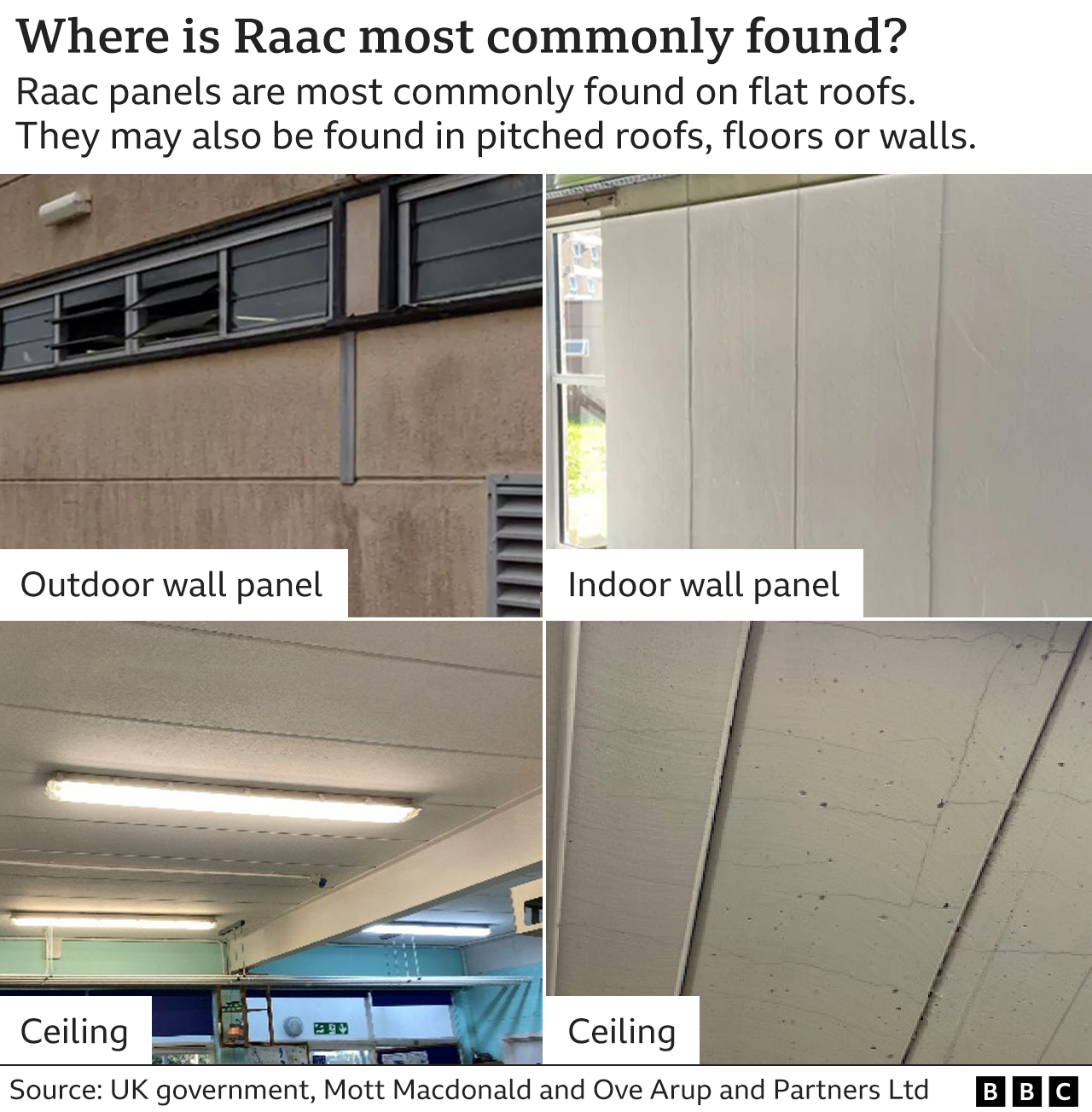

RAAC is a lightweight, 'bubbly' form of concrete that was commonly used in school and other buildings from the mid-1960s to the mid-1980s. RAAC is mainly found in roofs, although occasionally in floors and walls. RAAC is less strong than traditional concrete and there have been problems as a result, which could have significant consequences.

Concrete expert explains problem with RAAC concrete Channel 4 News

This guidance provides identification and remediation solutions for Reinforced Autoclaved Aerated Concrete (RAAC) planks. RAAC has been used in building structures in the UK and Europe since the late 1950's, most commonly as precast roof panels in flat roof construction, but in the 1990s structural deficiencies became apparent.

The dangers of RAAC concrete is your school at risk? Netmums

However, there is no central register of buildings with RAAC roof planks - or floor or wall panels - and so identification depends on local knowledge and independent inspections. Department for Education (DfE) guidance also outlines the following simple principles for identification purposes. Typically, panels are 600mm wide.

Expert explainer What is Reinforced Autoclaved Aerated Concrete (RAAC) and why are people

Through our RAAC expert partnerships we can design, cost and implement the works quickly and efficiently. RAAC REMOVAL & RENEWAL: With a RAAC time expired life span of 30 years, removal and replacement is often required. With our partners we can design the most cost and time efficient solution to achieve this.

AAC Autoclaved Aerated Concrete PSE Consulting Engineers

It has been produced to help estates' teams/site managers understand how to identify. Reinforced Autoclaved Aerated Concrete (RAAC) panels in floors, walls, eaves and roofs (pitched and flat). This publication replaces previous guidance issued by the DfE entitled 'Reinforced Autoclaved Aerated Concrete: Estates guidance' dated December 2022.

What is RAAC concrete and why is it a safety risk? BBC News

STEP 2 - If RAAC is present, we can provide a technical report and recommendations for next steps. This may include surveying the RAAC planks to identify any structural issues which a Structural Engineer would then use as part of a remedial works proposal. STEP 3 - We work with many of the UK's leading structural engineers and can use.

RAAC Reinforced Autoclaved Aerated Concrete How to identify it and what to do about it

Traditional concrete, precast or ready-mixed, is used with reinforcement, but this concrete is resilient to water ingress and protects the reinforcing bars. The IStructE notes that traditional concrete is a highly reliable material with high compressive strength, that when combined with steel reinforcement to become 'reinforced concrete.

Crumbling Reinforced Autoclaved Aerated Concrete (Raac) in Schools Leads to Asbestos Exposure

RAAC is a form of concrete developed in Sweden in the 1920's and introduced in the UK in the 1950's. It was commonly used in construction of public sector buildings until the mid-1990's in our country. RAAC is a lightweight 'bubbly' material commonly found in roofs, floors, and walls. It is made with cement, blast furnace slag, and.

RAAC What now for buildings affected by the structurally unsound material? New Civil Engineer

Concrete (RAAC) and appoint an appropriately qualified building surveyor or structural engineer to confirm if RAAC is present in their settings.. RAAC and give advice on how you can safely identify RAAC panels in your buildings. Failure of reinforced autoclaved aerated concrete (RAAC) planks

RAAC concrete scandal What developers, freeholders and leaseholders need to know

RAAC: Advice and FAQs. This page contains answers to frequently asked questions and advice for the public and members regarding Reinforced Autoclaved Aerated Concrete (RAAC). The below link provides guidance from the government for responsible bodies and education settings with confirmed RAAC. Reinforced autoclaved aerated concrete: guidance.

What is the problem with Reinforced Autoclaved Aerated Concrete (RAAC)? Surveyors to Education

Identifying a RAAC roof. As there is no central register of buildings that used RAAC roof planks, a physical inspection is the best way to identify if your roof deck is constructed using RAAC. Due to the potential dangers involved, a detailed risk assessment must be carried out. A safe system of work can then be planned to allow this.

‘Hundreds’ of schools could still contain RAAC plus latest updates

Guidance advises responsible bodies and settings on how to identify RAAC and what they should do if it is confirmed, including vacating and restricting access to the spaces with confirmed RAAC.

RAAC Identification Surveys and Testing Sandberg

The attached document provides guidance on: the identification of RAAC. the appointment of a building surveyor or structural engineer to confirm if RAAC is present in any of the buildings on your.

How to identify RAAC (Reinforced Autoclaved Aerated Concrete) harrisonclarke.co

How to identify RAAC concrete. Identifying RAAC concrete is fairly straightforward because the panels usually have a chamfered edge, says Andrew. This gives the appearance of V shaped grooves every 600mm on the surface of the roof. RAAC is also more lightweight than traditional concrete, but it's not a good idea to attempt to dig into it as.